Salt spray tests are a type of accelerated corrosion test that are used to evaluate the corrosion resistance of materials. In a salt spray test, the material is exposed to a salt mist for a period of time, typically 24 hours to 2,000 hours. The salt mist causes the material to corrode more quickly than it would in a normal environment.

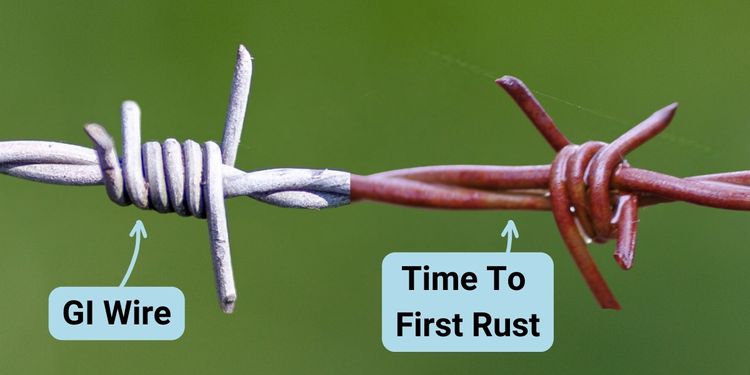

The protective patina that forms on galvanized steel is a thin layer of zinc carbonate. The zinc carbonate is formed when the zinc reacts with the carbon dioxide and moisture in the air. The patina layer protects the underlying steel from corrosion.

In a salt spray test, the constant salt exposure prevents the patina layer from forming. This is because the salt mist is too acidic and corrosive for the patina to form. However, in real-world applications, the patina layer will form after a few months of exposure to the weather.

The patina layer is important for the long-term durability of galvanized steel. It protects the steel from corrosion and helps to extend its lifespan.